Causes of stop marks on circular knitting fabrics

In the knitting process of the circular knitting machine, when the machine starts and stops, sometimes a circle of horizontal marks will be produced on the cloth surface, which is generally called the stop mark. The occurrence of downtime marks is related to the following reasons:

1) There is a gap due to wear of the yarn feeding shaft key

2) The friction coefficient between the yarn feeding aluminum plate and the teeth belt is too small, causing slippage

3) The take down roller of the winder is too loose, causing the cloth to pull back; or there is a problem with the transmission of the take down, and the cloth winder is lagging.

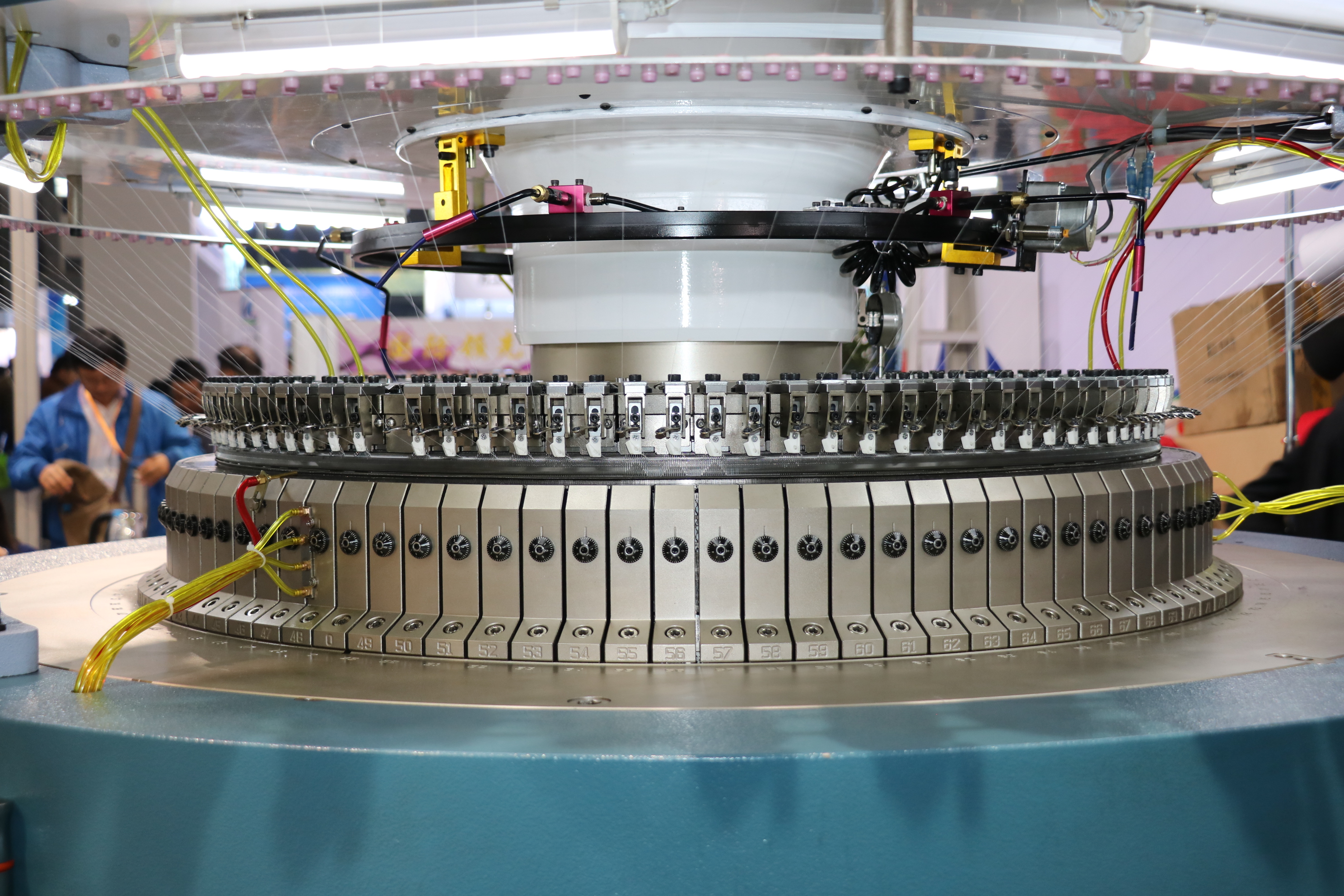

4) The fit between the cam track and the knitting needles or sinkers is too loose (the coordination between the cam track and the knitting needles is related to the thickness of the knitting needles used, thick knitting needles are tightly matched, and thin knitting needles will be looser.-Sets It is not advisable to use a too large range of stitch length for the cam). When the cam track is too loose with the needles, the cloth surface will be dense and the yarn feeding tension will be loose when driving slowly; when driving fast, the cloth surface will become thinner and the loose yarn tension will become tight.

5) If the cambox is adjusted centrally, the design and manufacture are unreasonable, and it is more prone to stop marks.

6) The same problem will occur if the double jersey knitting machine is too loose between the big tripod gear or the large plate gear and the pinion gear. It is easy to cause the upper and lower needle cylinders to shake when starting or braking, which affects the alignment of the upper and lower knitting needles.